Overview of rotary vane vacuum pump

Rotary vane vacuum pump (referred to as rotary vane pump) is an oil sealed mechanical vacuum pump.Its working pressure range is 101325~1.33×10 -2 (Pa) belongs to low vacuum pump.It can be used alone or as the front pump of other high vacuum pumps or ultra-high vacuum pumps.It has been widely used in the production and scientific research departments of metallurgy, machinery, military, electronics, chemical industry,light industry, petroleum and medicine.

The rotary vane pump can pump out the dry gas in the sealed container.If there is a gas ballast device,it can also pump out a certain amount of condensable gas.However, it is not suitable for pumping out gases with excessive oxygen content,corrosiveness to metals, chemical reaction to pump oil and particles and dust.

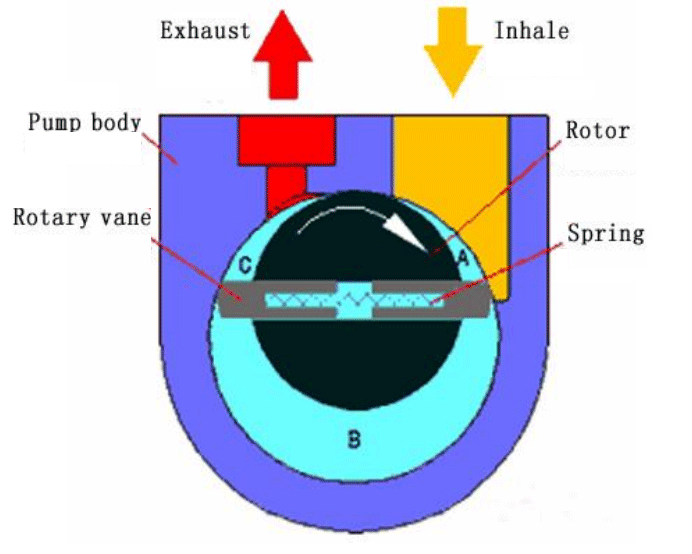

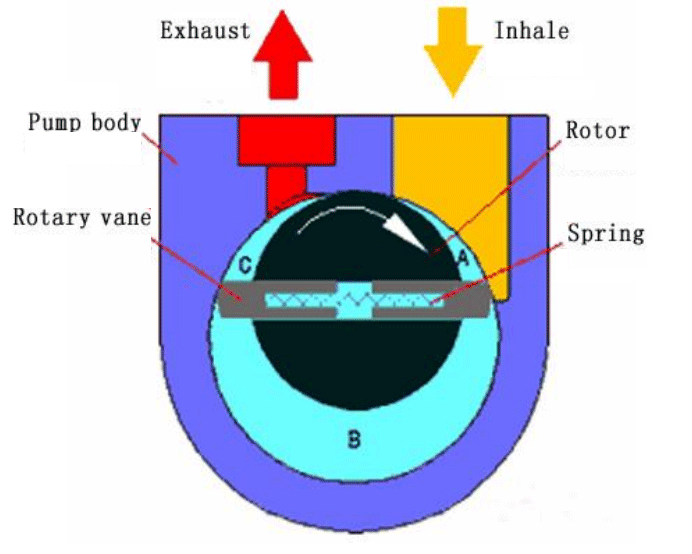

Working principle

Rotary vane pump is mainly composed of pump body, rotor, rotary vane, end cover,spring,etc. A rotor is eccentrically installed in the cavity of the rotary vane pump.The outer circle of the rotor is tangent to the surface of the pump cavity(there is a small gap between the two). Two rotary vanes with springs are installed in the rotor slot.During rotation,the centrifugal force and the tension of the spring keep the top of the rotary vane in contact with the inner wall of the pump chamber, and the rotation of the rotor drives the rotary vane to slide along the inner wall of the pump chamber.

The crescent shaped space enclosed by the rotor,pump chamber and two end covers is separated into three parts,A,B and C,as shown in the figure.When the rotor rotates in the direction of the arrow,the volume of space A connected to the suction port is gradually increasing and is in the process of suction.The volume of space C connected with the exhaust port is gradually reduced,and is in the process of exhaust.The volume of space B in the center is also gradually decreasing and is in the process of compression.As the volume of space A increases gradually(i.e. expands),the gas pressure decreases,and the external gas pressure at the pump inlet is greater than that in space A,so the gas is inhaled.

When space A is isolated from the air inlet, it turns to the position of space B, and the gas starts to be compressed, the volume gradually shrinks, and finally it is connected with the air outlet. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas is discharged into the atmosphere through the oil layer in the oil tank. The continuous operation of the pump can achieve the purpose of continuous air extraction. If the discharged gas is transferred to another stage (low vacuum stage) through the air passage, it is pumped by the low vacuum stage, and then compressed by the low vacuum stage and discharged to the atmosphere, forming a two-stage pump. At this time, the total compression ratio is borne by two stages, thus increasing the limit vacuum degree.

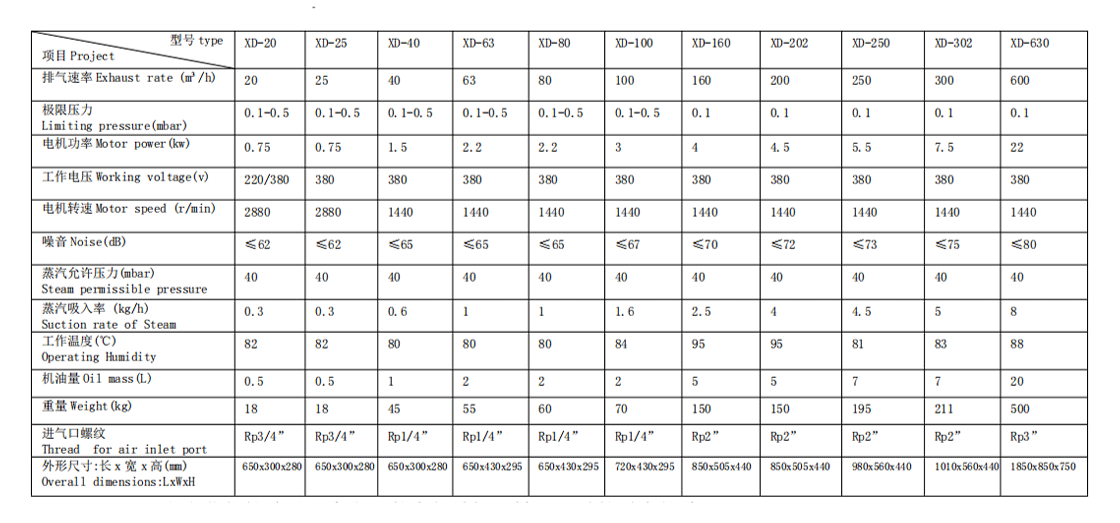

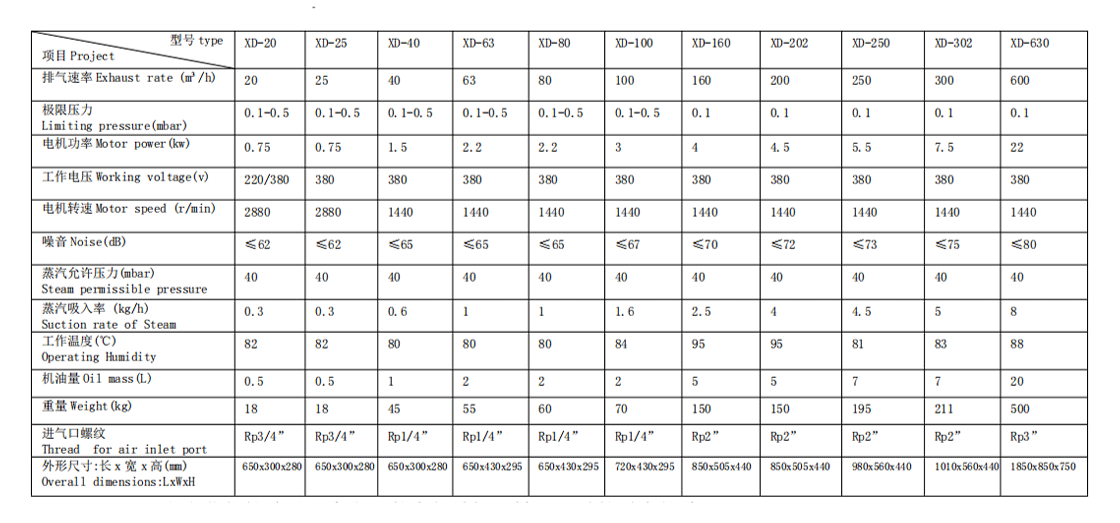

Technical parameter

Factory Shooting

Workshop shooting, complete equipment, and rich production experience