operational principle

Dry screw vacuum pump is a device that uses screw rotation to generate vacuum. It mainly consists of two screws, one rotating clockwise and the other rotating counterclockwise. These two screws rotate synchronously at high speed in the pump casing, producing suction and exhaust effects, thereby achieving the purpose of extracting gas.

Technical parameter

Type

(Air cooled series) | Basic parameters |

Pumping speed

(m3/h) | Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber

(mm) | outlet caliber (mm) | Pump head weight

(kg) | noise dB(A) | Overall dimension

(length*width*height)

(mm) |

| LG-10 | 10 | ≤5 | 0.75 | 2730 | KF16 | KF16 | 30 | ≤ 72 | 655x260x285 |

| LG-20 | 20 | ≤5 | 1.1 | 2840 | KF25 | KF25 | 55 | ≤72 | 720x305x370 |

| LG-50 | 50 | ≤10 | 2.2 | 2850 | KF40 | KF40 | 90 | ≤75 | 920x350x420 |

| LG-70 | 70 | ≤30 | 3 | 2850 | KF40 | KF40 | 110 | ≤75 | 910x390x460 |

| LG-90 | 90 | ≤30 | 4 | 2870 | KF50 | KF50 | 125 | ≤80 | 1000x410x495 |

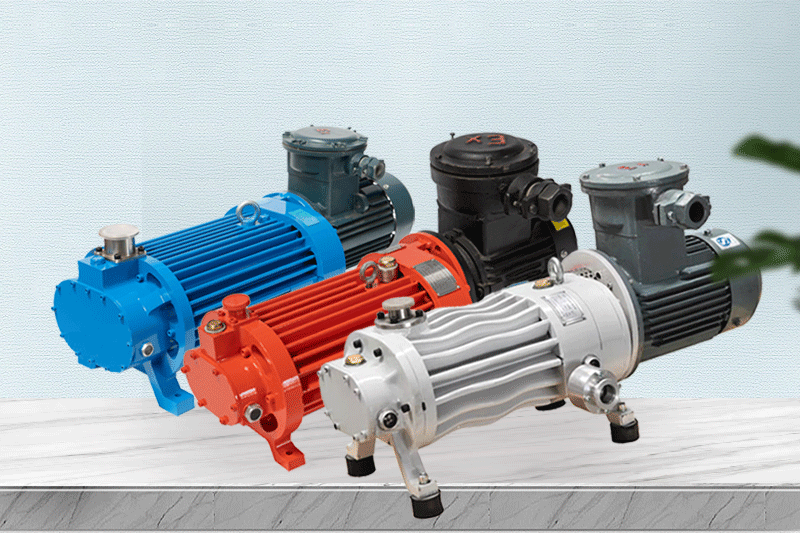

Water cooling Dry screw vacuum pump

application area

1.Semiconductor industry: Dry screw vacuum pumps can be used in processes such as wafer manufacturing, thin film deposition, and chemical vapor deposition in the semiconductor industry to extract residual gases and impurities.

2. Medical and pharmaceutical industries: In the pharmaceutical and medical fields, dry screw vacuum pumps can be used in sterilization, distillation, freeze-drying, and purification processes to help maintain a highly clean environment and stable pressure.

3. Photovoltaics: Dry screw vacuum pumps can be used in the production of solar panels to remove impurities and odors during the production process.

4. Food industry: dry screw vacuum pump is used for spices, essence, food packaging, etc. Specific applications, vacuum distillation, molecular distillation, solvent recovery, oil and gas recovery, general vacuum in factories, electronics, and vacuum coatings.

5. Aviation and nuclear industries: can remove ordinary air, flammable and explosive gases, corrosive gases, especially in environments that require high levels of clean vacuum. For example: vacuum coating, vacuum distillation, vacuum drying, single crystal pulling, special gas manufacturing, ion etching, etc.

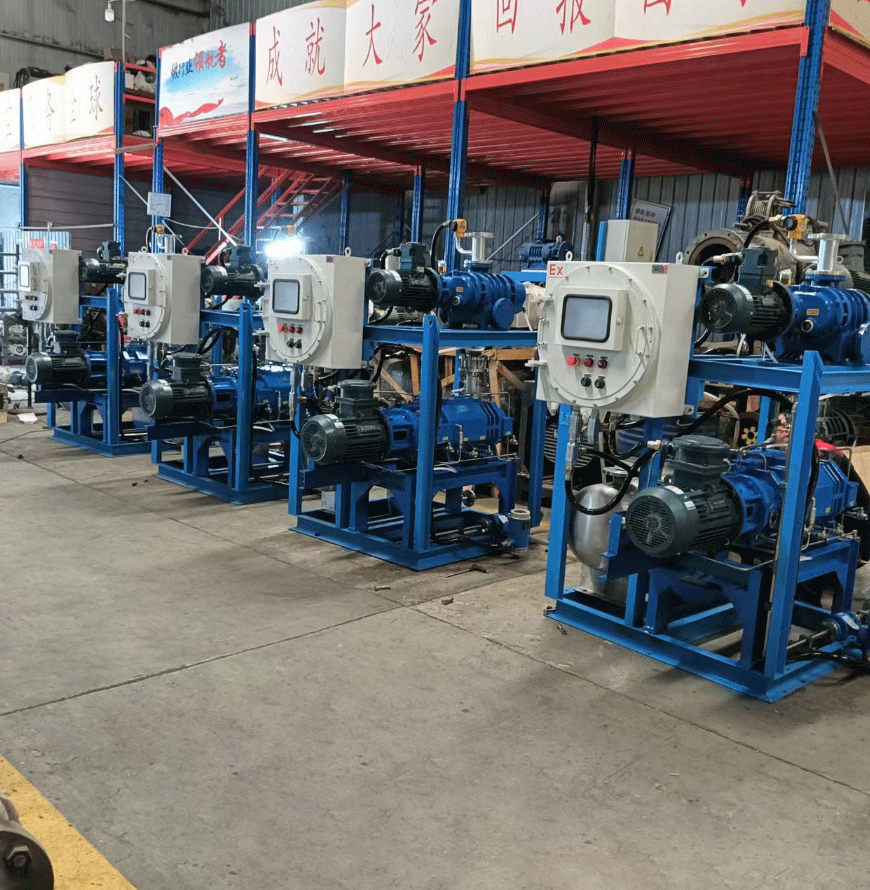

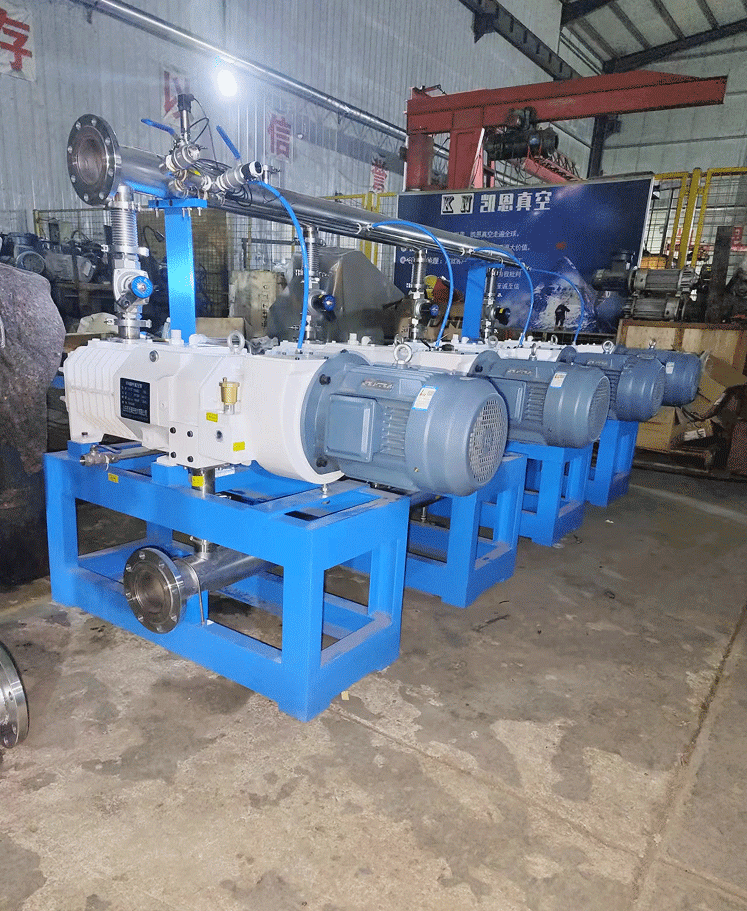

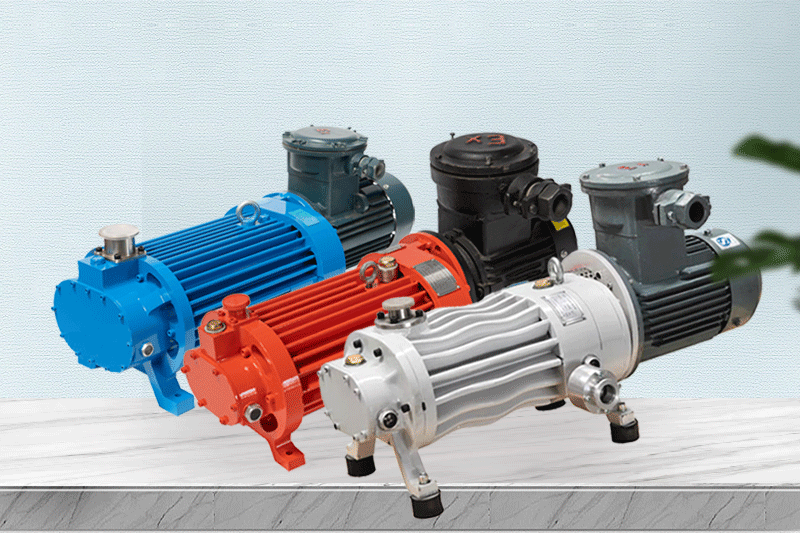

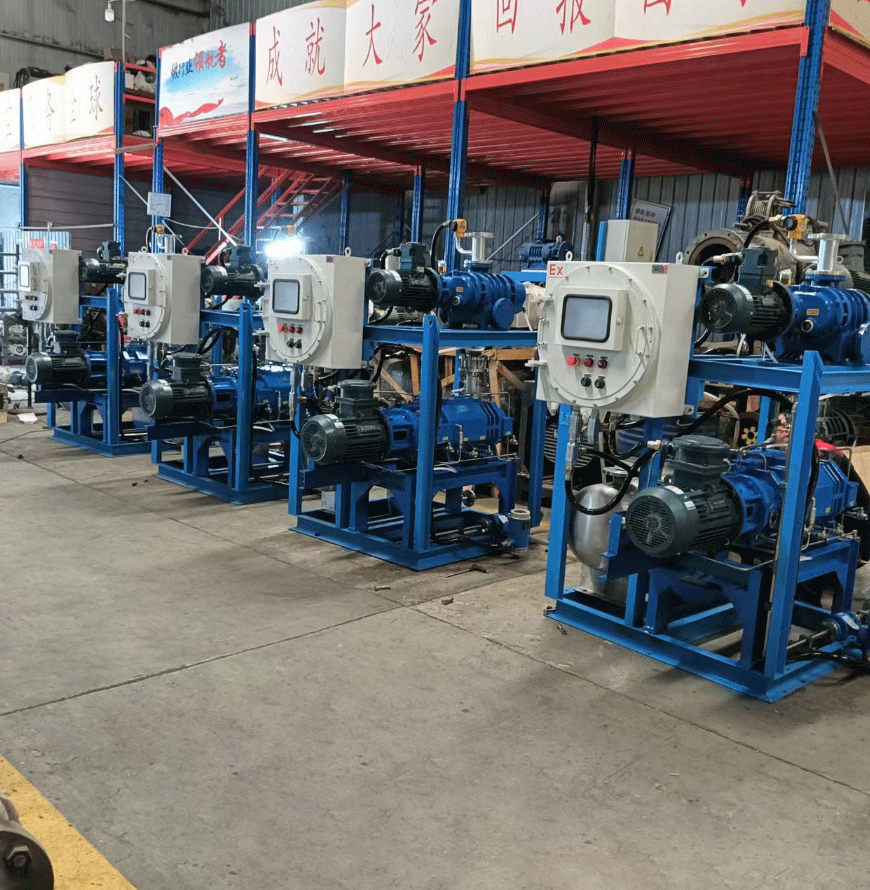

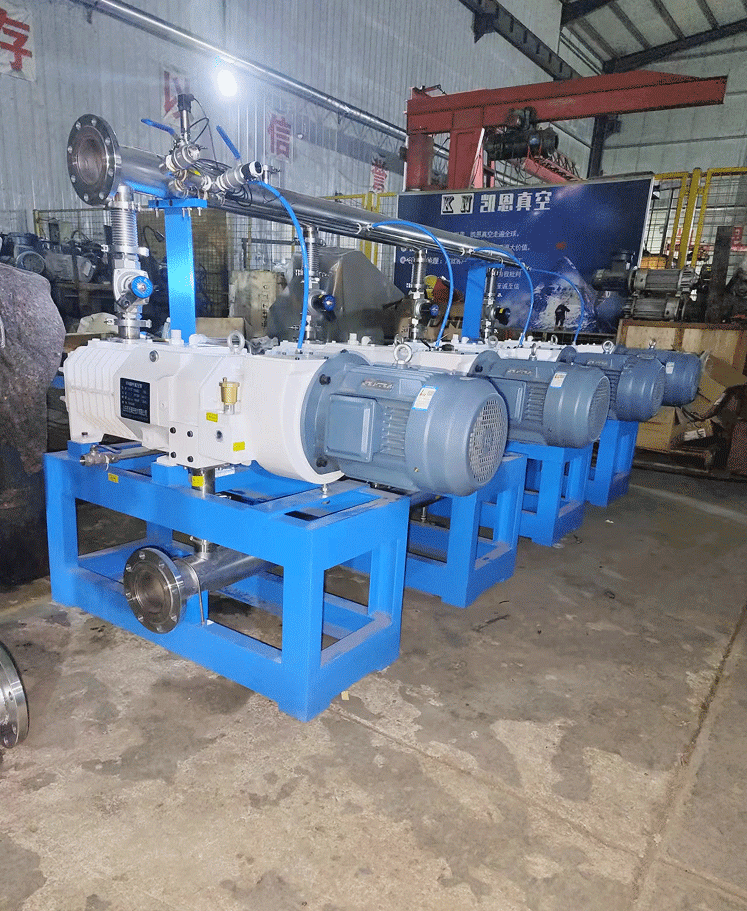

Factory Shooting

Workshop shooting, complete equipment, and rich production experience