Product Description

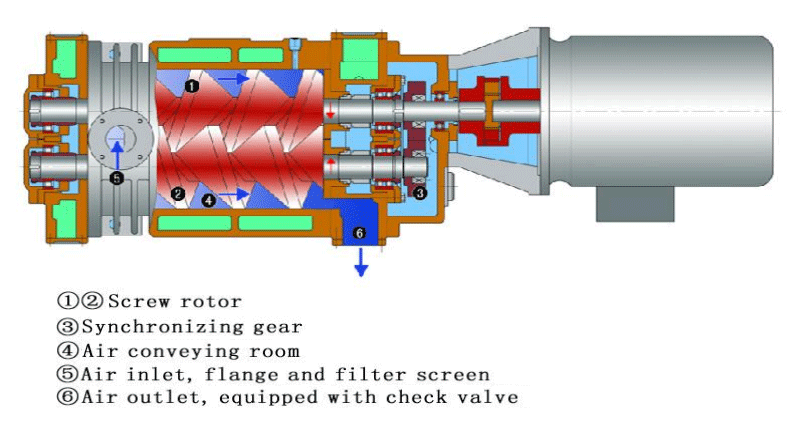

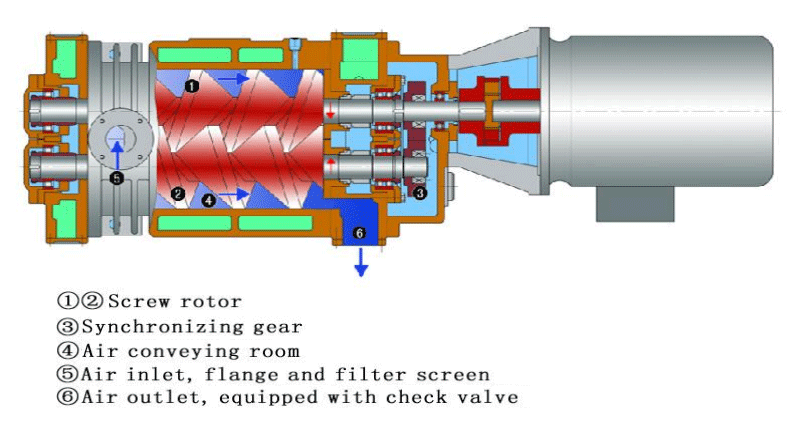

The dry screw vacuum pump is a rotor that uses a pair of parallel screws to make synchronous, high-speed and reverse rotation in the pump housing. The rotor and the inner wall of the pump body form a number of sealing spaces. During the rotation, the continuous transmission of gas is formed to achieve the purpose of suction and exhaust.

The screw vacuum pump has a simple structure, but its processing technology requires higher requirements. It must ensure that the height between rotors is parallel, and that between rotors and between rotors and the inner wall of the pump body, there is a very small gap and no friction caused by contact, so as to ensure the realization of gas transmission and reduce gas backflow without the need for oil lubrication and sealing.

LG-20Technical parameters of screw vacuum pump

Type

(Air cooled series) | Basic parameters |

Pumping speed

(m3/h) | Presure limit (Pa) | Power (kW) | revolution (rpm) | Inlet caliber

(mm) | outlet caliber (mm) | Pump head weight

(kg) | noise dB(A) | Overall dimension

(length*width*height)

(mm) |

LG-10 | 10 | ≤5 | 0.75 | 2730 | KF16 | KF16 | 30 | ≤72 | 655x260x285 |

LG-20 | 20 | ≤5 | 1.1 | 2840 | KF25 | KF25 | 55 | ≤72 | 720x305x370 |

LG-50 | 50 | ≤10 | 2.2 | 2850 | KF40 | KF40 | 90 | ≤75 | 920x350x420 |

LG-70 | 70 | ≤30 | 3 | 2850 | KF40 | KF40 | 110 | ≤75 | 910x390x460 |

LG-90 | 90 | ≤30 | 4 | 2870 | KF50 | KF50 | 125 | ≤80 | 1000x410x495 |

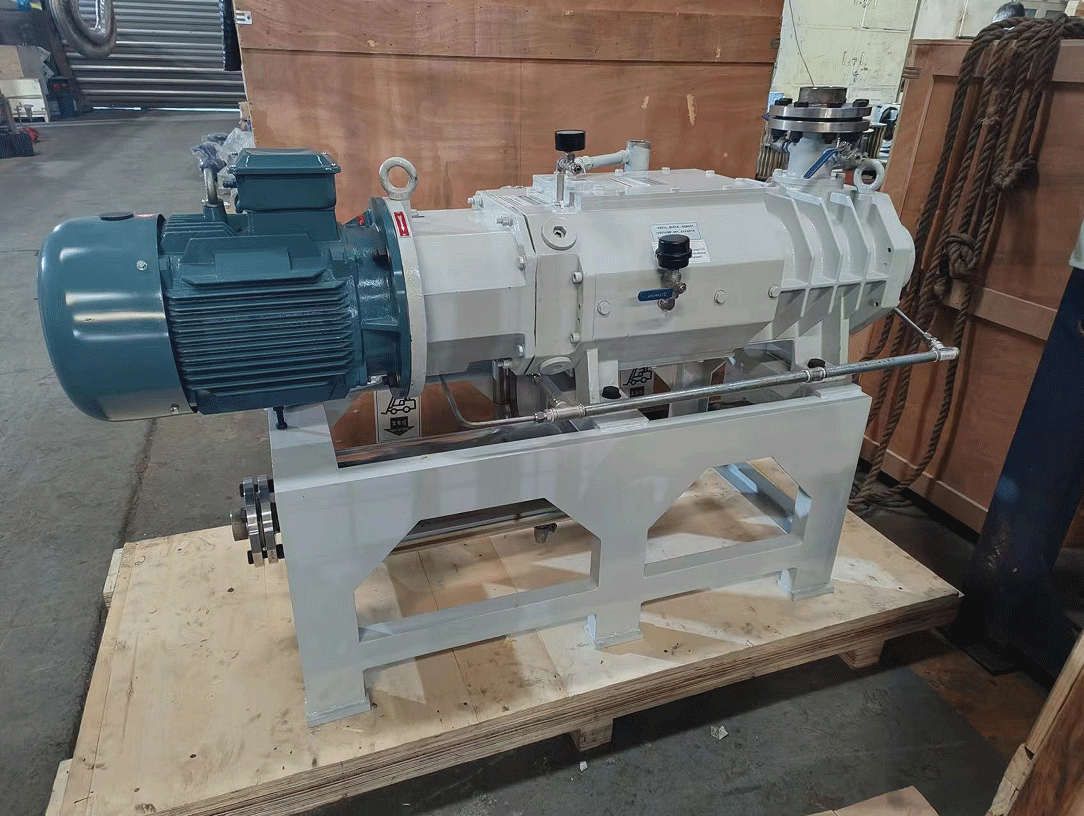

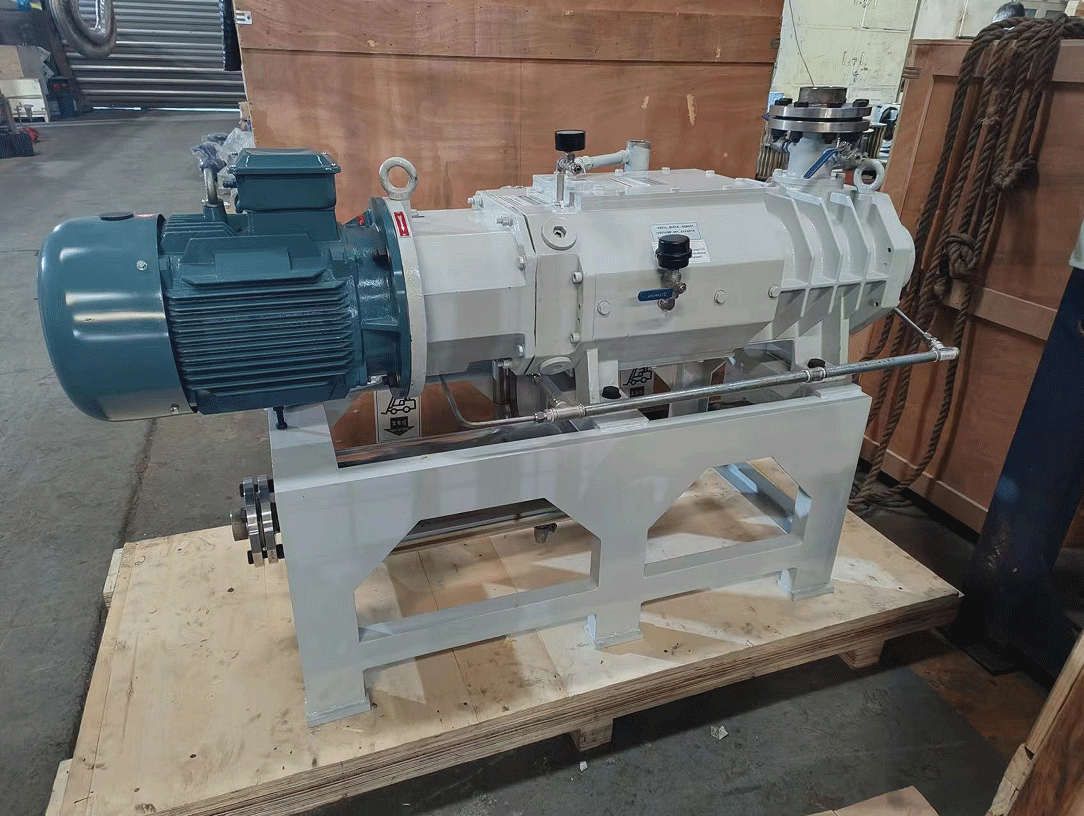

Water cooling Dry screw vacuum pump

Application Area

Can extract condensable gases containing a large amount of water vapor and a small amount of dust, and can also be used to extract corrosive gases, oil and gas, solvents, and other media for recovery.

The advantages of dry screw pumps

1、Clean and environment-friendly, the working chamber is free of lubricating oil, which is conducive to medium recovery, can obtain clean vacuum, no oil consumption, waste water discharge, and no pollution to the environment.

2、The vacuum degree is high, the limit vacuum degree is ≤ 1Pa, and the pumping capacity in the high vacuum area is large.

3、The anti-corrosion design is optional. The flow passage parts are made of titanium, stainless steel, nano ceramics, spraying NIP alloy and other materials and anti-corrosion coatings.

4、The condensable gas and a small amount of dust gas can be removed, and an automatic purging device is designed.

5、Special shaft seal design prevents mutual pollution between pumped medium and lubricating oil.

6、Variable pitch screw pump saves energy and has low noise.

7、The operation is stable, the rotor is subject to fine dynamic balance test, and the operation vibration is small.

8、High configuration, sealed in Germany, bearing SKF/NSK, gear grade 5 grinding.

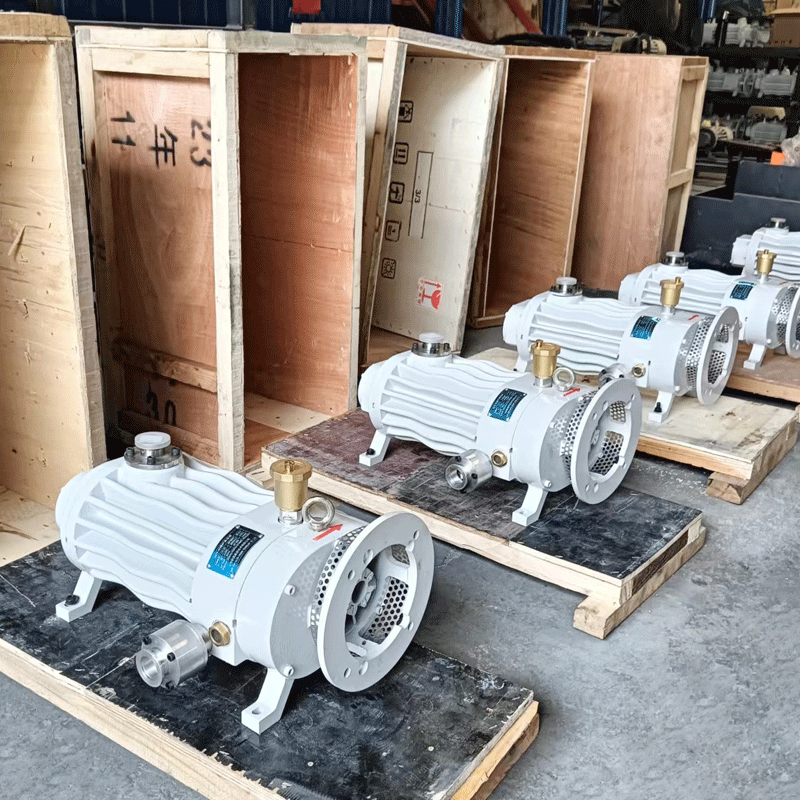

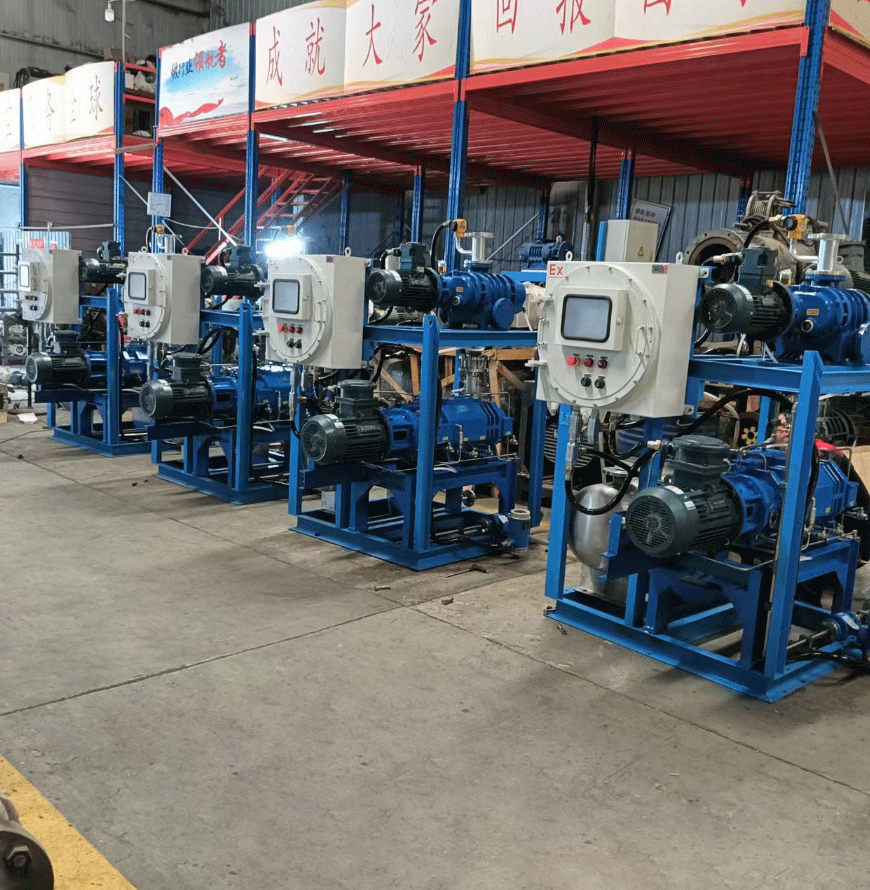

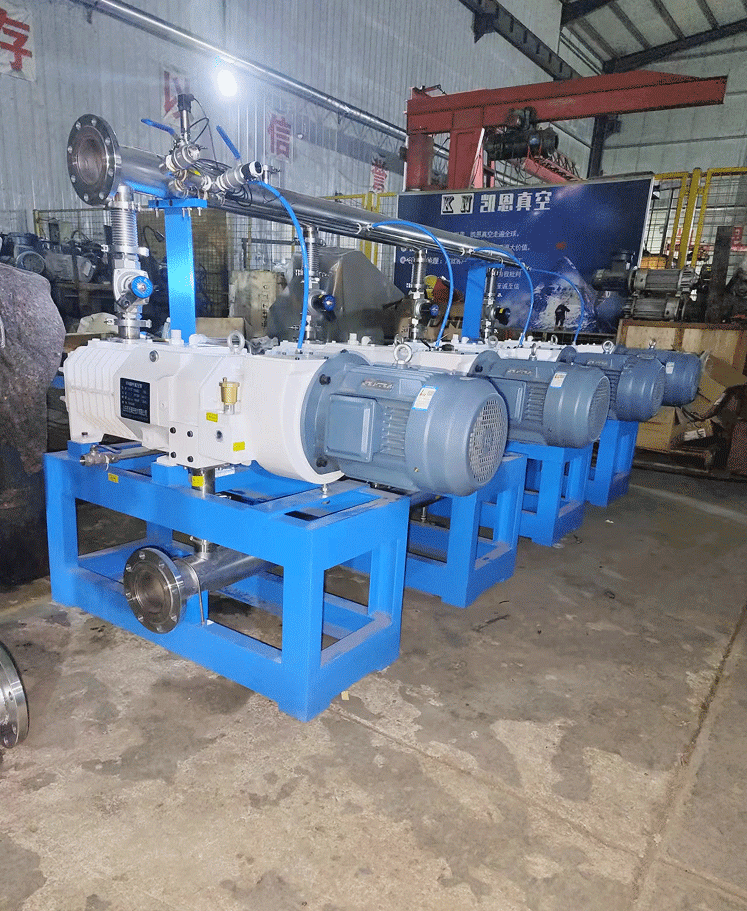

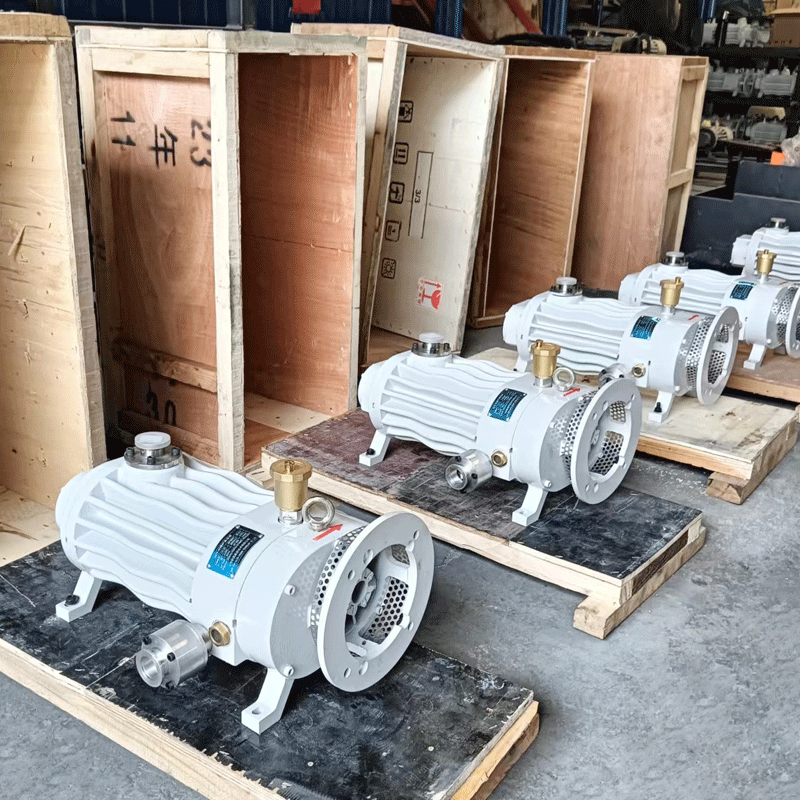

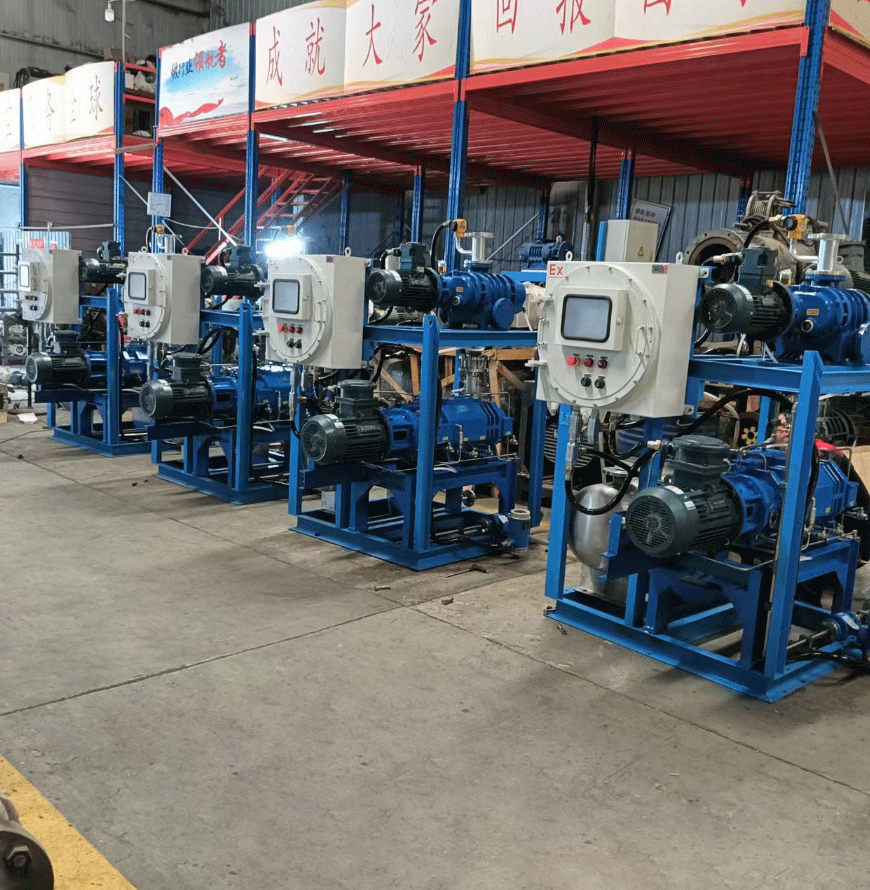

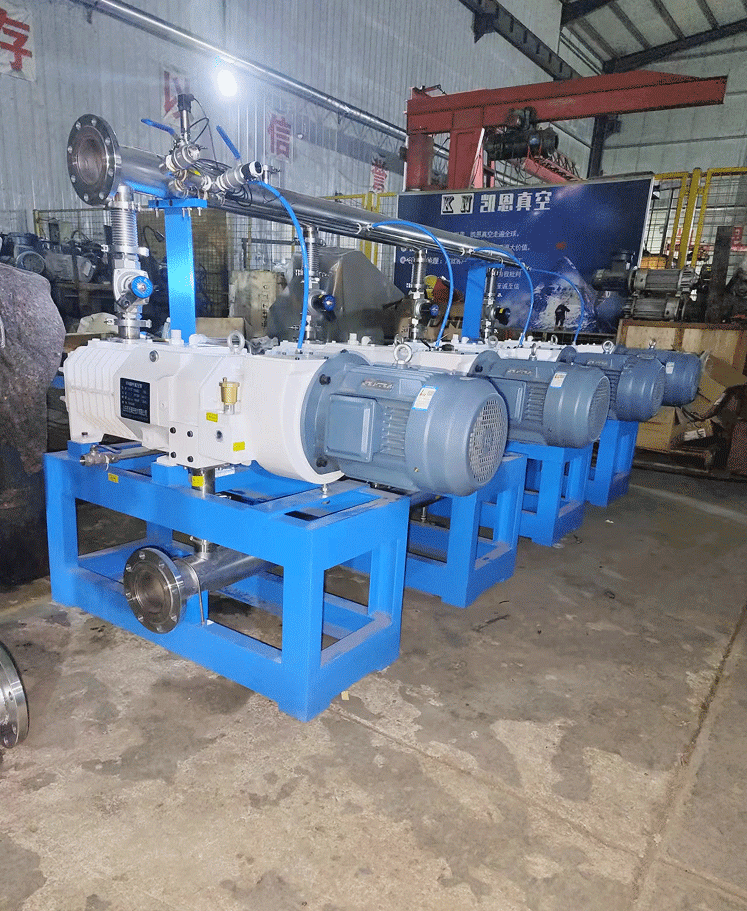

Factory Shooting

Workshop shooting, complete equipment, and rich production experience