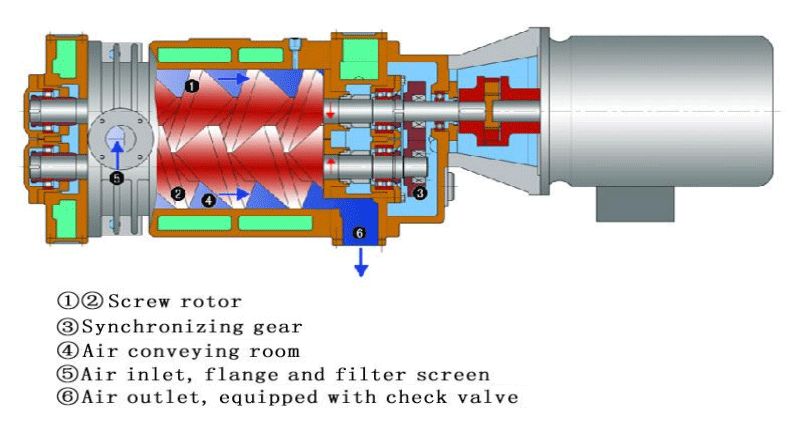

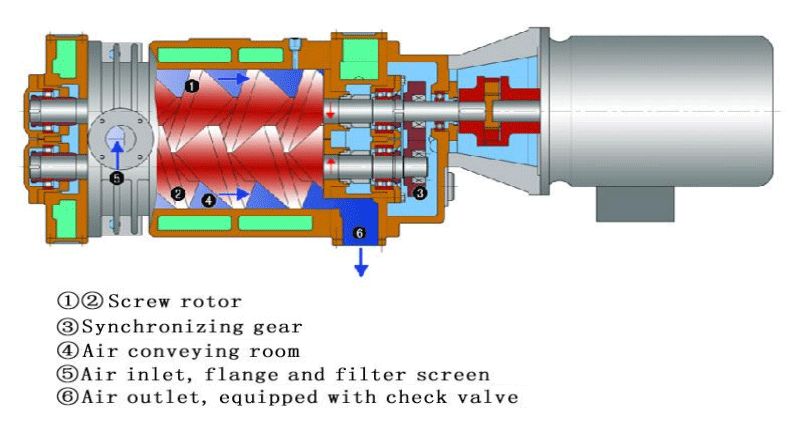

The dry screw vacuum pump is a rotor that uses a pair of parallel screws to make synchronous, high-speed and reverse rotation in the pump housing. The rotor and the inner wall of the pump body form a number of sealing spaces. During the rotation, the continuous transmission of gas is formed to achieve the purpose of suction and exhaust.

Definition and working principle of vacuum pump

The screw vacuum pump has a simple structure, but its processing technology requires higher requirements. It must ensure that the height between rotors is parallel, and that between rotors and between rotors and the inner wall of the pump body, there is a very small gap and no friction caused by contact, so as to ensure the realization of gastransmission and reduce gas backflow without the need for oil lubrication and sealing.

This requires that the entire product must be the highest standard from material selection to processing. Because the clearance between components is required to be very small, it is necessary to ensure that the screw and pump body materials are not easy to deform, especially when the temperature changes to a certain value, the locking phenomenon cannot occur due to deformation. Special material treatment shall be selected to ensure the fine processing of all parts. In addition to the fine processing of the two screws, dynamic balance correction shall be carried out. The shaft end bearing must be a high-quality special bearing, which not only ensures the parallelism of the screw rotor and is not prone to slight displacement, but also ensures smooth rotation and is not affected by temperature and other factors. When the vacuum pump is working, the clearance between them is small without friction, the operation is stable, the vibration is small, the noise is low, the energy is saved, and the service life is extended. The special screw structure can continuously promote the air flow without compression. The exhaust port is lower than the screw position, the liquid discharge capacity is strong, and it is easy to clean. The pump cavity has short channels, no partitions, and the exhaust and discharge are smooth, so the working efficiency is high, the suction is super strong, and the limit vacuum degree of the pump is greatly improved, It can provide high vacuum ≤ 5Pa or even close to 1Pa; There is no lubrication and pollution in the working chamber, which can provide a clean vacuum without worrying about backflow pollution. Extracts can also be directly recycled or discharged without environmental pressure. Elaborate design, simple structure and precise processing make it more convenient to use and easier to maintain,which is favored by many industry users. It is widely used, not only to extract condensable gas, but also to extract gas containing a large amount of water vapor and a small amount of dust. The specially treated overflow surface can also be used to extract certain corrosive gas, and it is also a special product for oil and gas recovery, solvent recovery, special gas recovery and other industries.