Descriptio

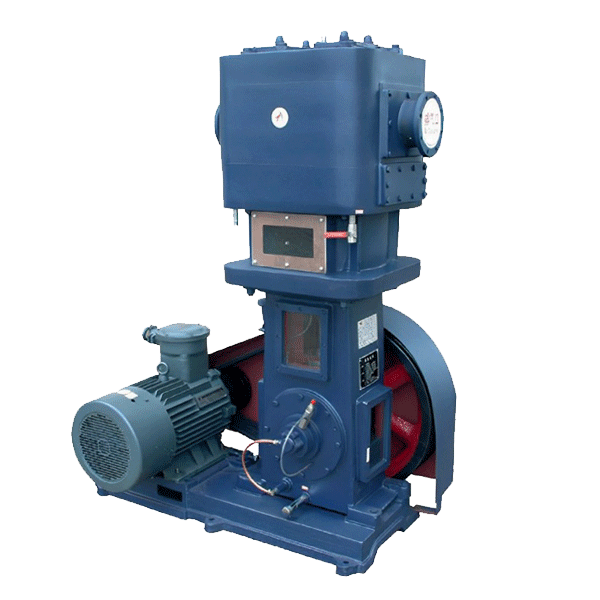

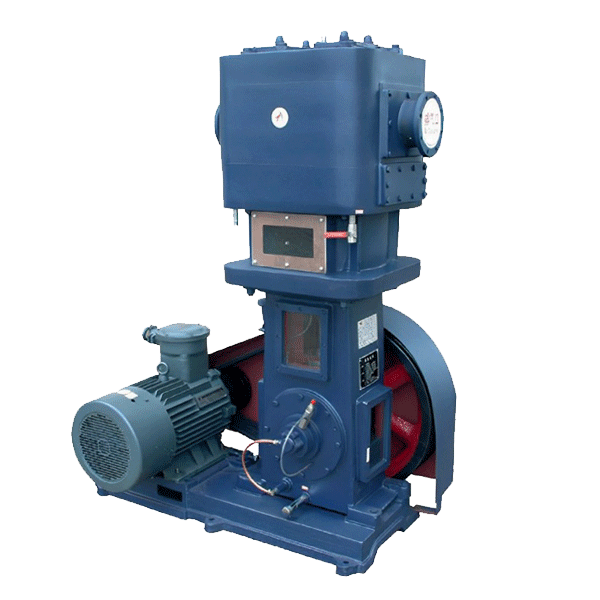

In WL et WLW series verticalis (oleum-libera) reciprocus vacuum soleatus sunt nationalis major novus products. Comparari WY Series Vestibulum reciproco vacuo exhalata, habent sequenti commoda:

I, nec oleum lubricatae, potest consequi mundum vacuo environment;

2,1 / III Inferior potentia consummatio et 2/3 minus vestigium;

III, axial Ordinatio caeli valvae facit facile ad agunt et ponere, et habet longam muneris vitae;

IV, eliminated inferior fluctus vibrationem, unde in humilis tremor et low strepitu.

Et WLW series vertical oleum-liberum reciprocus vacuum sentinam lautus cum duabus incremento gazofilacia inter cylindrici et corpus, unum inerti Gas incremento camera et unum recuperatio gas incremento. Cum removere fomes explosivae et toxicus vapores, inerti Gas replendum ne aere (combustione auxilium) ab stilutione in cylindri, ita vitandum accidentia; Cum Gas indiget recuperari, recuperata Gas potest impleri curare puritatem recuperavit Gas.

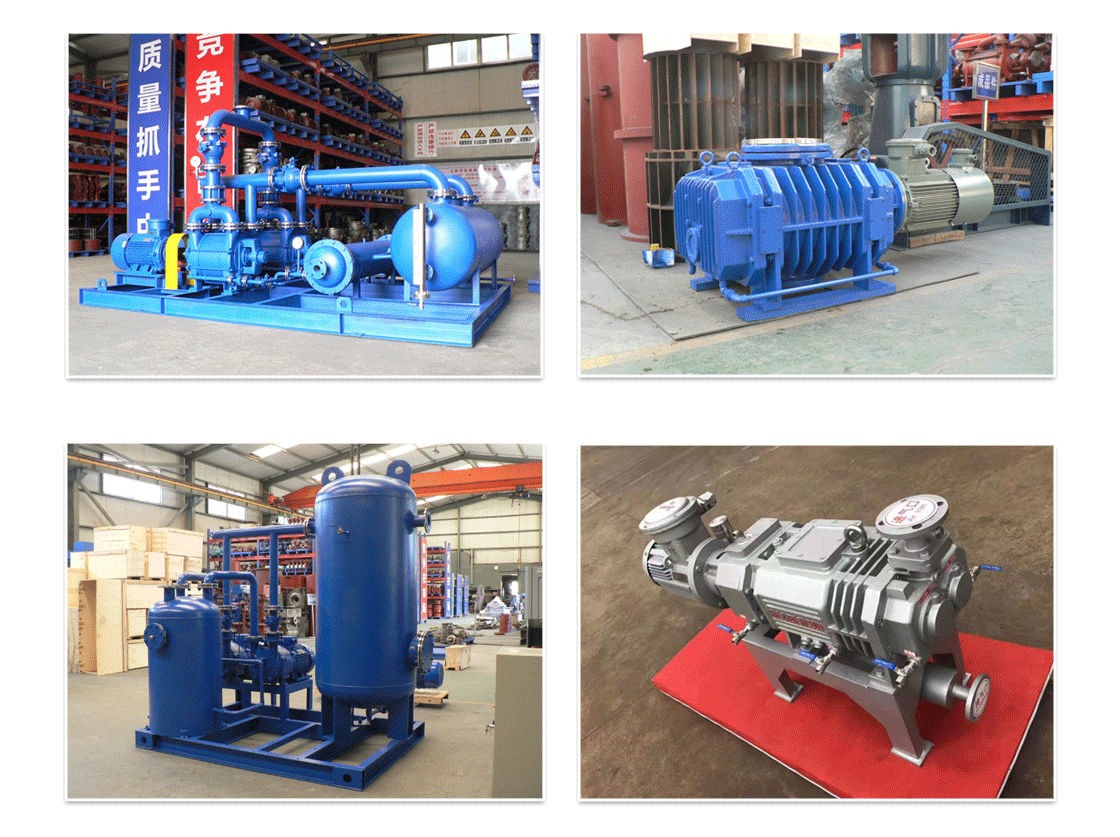

applicationem regio

Hoc series vertical (oleum-libera) reciproco vacuo soleatur late in vacuo, conflans, Distillation, concentration, adsorption, siccatio et alia industries ut pharmaceuticals, et siccatio et alia industries, ut pharmaceuticals, et alias industrias, et cibum.

Technica modularis

Euismod parametri

type |

Pumping celeritate (l / s) |

Pressura terminum (PA) |

Revolution (RPM) |

Electrica machinery |

Caliberi de Aeris Instet et Outlet (mm) | (° F)

Pump Temperature |

| Genus | (KW)

Power |

| WLW-L | 50 |

| 270 | Y132m1-6 | 4 | 0) L |

|

| WLW-LXX | 70 |

| 380 | Y132m2-6 | 5.5 | 050 |

|

| WLW C-C | 100 |

| 350 | Y160m-VI | 7.5 | 0100 |

|

| WLW-CL | 150 |

| 310 | Y160l-VI | 11 | 0125 |

|

| WLW-CC | 200 | 2000 | 310 | Y180l-VI | 15 | 0125 | W40 |

| WLW-CCC | 300 |

| 250 | Y200l2-6 | 22 | 0160 |

|

| Wlw CD | 400 |

| 250 | Y225m-VI | 30 | 0160 |

|

| WLW-DC | 600 |

| 240 | Y280s-VI | 45 | 0250 |

|

| WLW-MCC | 1200 |

| 260 | Y315M-VI | 90 | 0320 |

|

Opus

In WLW series est unum cylindri, una scaena, duplex agens piston sentinam

I, mechanica transmissione components: repulsi per a motricium per a V-balteus, in crank labor mechanism agitati praestare reciprocating motus, et lapsus (crosshead in Piston virga reciprocating ad Piston per Piston virga.

II, suctionis et exhauriunt components: Piston sulcus instructa expansion annulos, dux annulos et Piston annulos, quae movere et in cylindri formare expansionem et compressionem Gas intra cylindri. Et suctu et exhauriunt actiones perficitur per axially disposita attractio et exhauriunt CYMBALON.

III, auxiliariis muneris components: et lubricating oleum in crankcase lubricates movens partes per splashing oleum et superiori refrigerationem aquam peragit calidum generatae per Gas compress. Et Piston annulos in cylindrici sunt facta de F4 auto-lubricating materia, quae non requirit additional lubricatae.

IV, sarcina signantes components: dividitur in vulgares et speciale genera. In Ordinarius sarcina signantes materiam usus polytetrafluoroethylene sarcina aut fluororubber Os oleum sigillum.

Special Stacking Sigillum: A sarcina cylindrici sunt addita, specie disposito flammabiles et explosivae vapores (ut co, sicca Gas, methane, et aliis vaporibus cum excelsum environmental requisitis). Cum in usu, NITROGENIUM Gas cum quadam pressura et fluunt rate (lectus secundum processus conditionibus) introducitur. After two throttling cycles, it mixes with the working fluid that leaks into the mixing chamber and is led out of the system, thereby avoiding the danger of working fluid gas leakage into the environment and preventing air from entering the cylinder to pollute the raw materials.

5、Spacer: To prevent material leakage and contamination of the lubricating oil in the crankcase caused by the failure of packing components, a spacer component is installed to completely isolate the contact path between the overcurrent part and moving parts, ensuring absolute oil-free vacuum system.Especially suitable for environments such as exhaust gas recovery where materials have general corrosiveness, strong sensitivity to engine oil, or require extremely high cleanliness.

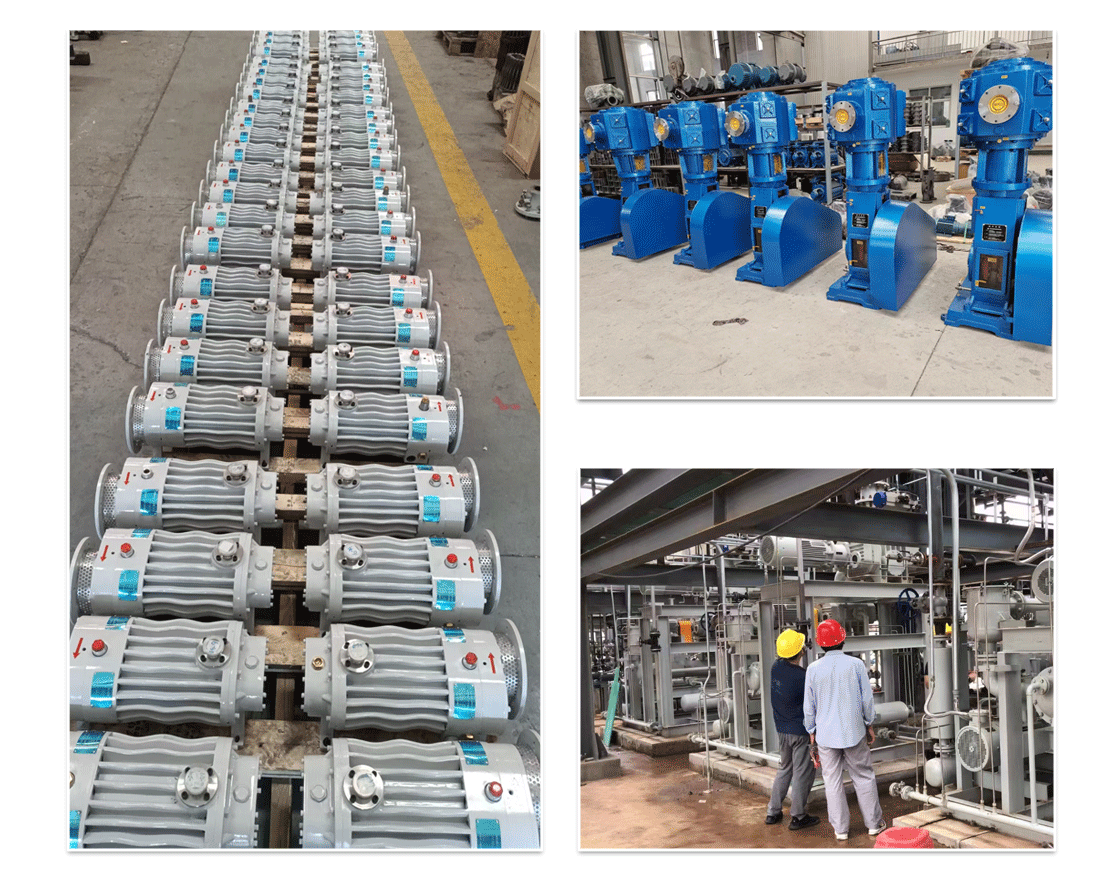

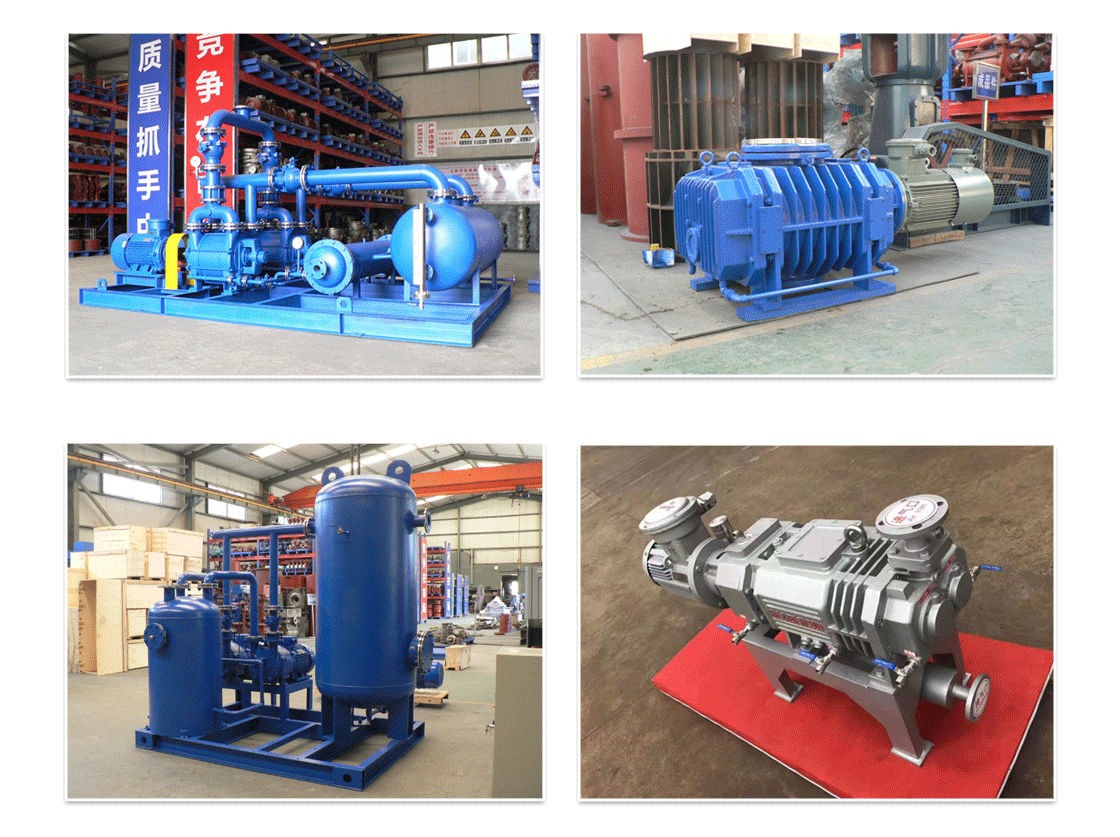

OFFICIUM

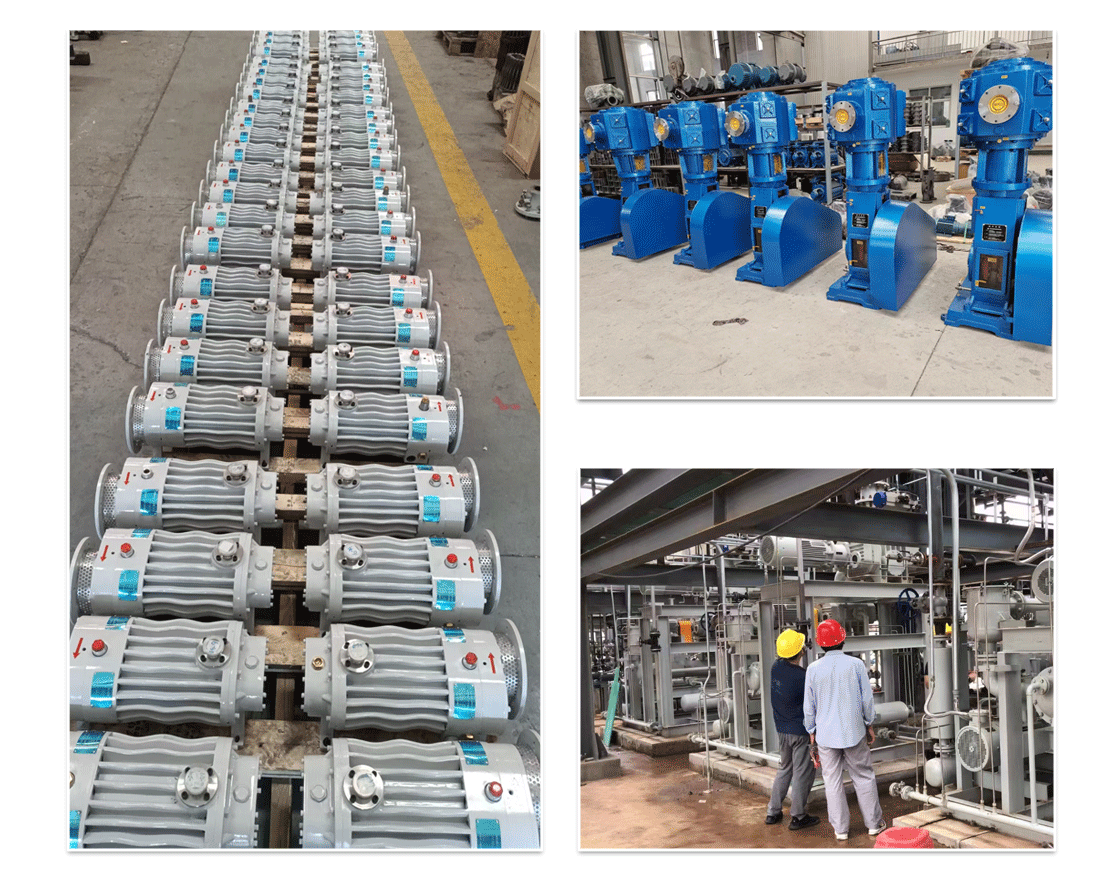

Workshop dirigentes, completum apparatu et dives productio experientia

Certificate auctor

Fortis technica vires, optimum apparatu, et products stricte managed ad normam ISO9001 qualis ratio.