Summary

KNCSB series vacuum churning sewage pump is a kind of pump equipment applied to non-gravity sewage discharge of ships. It integrates the functions of vacuum pumping, transportation and churning sewage. It has the characteristics of simple system, low flushing water volume, small sewage collection volume, small pipeline diameter, no inclination requirement, no blockage, flexible installation and layout, strong vertical lifting capacity, low investment and operating costs, and is applicable to modern ships, ships, trains, camping equipment,Pollution discharge from modern buildings, environmentally friendly kitchens, etc.

Features

▲ small size, light weight, quick and flexible installation.

▲ pipeline installation, direct discharge to sewer, sewage treatment plant or collection tank.

▲ multiphase design, the pump can pump and discharge gaseous, liquid and solid combined phases.

▲ low energy consumption.

▲ stainless steel and bronze anti-corrosion materials are used for long service life.

Performance parameters of KYJSB-120 vacuum mixing sewage pump

type | KYJSB-120 |

frequency Hz | 50Hz | 60Hz |

Suction frequency | 120 times / hour | 120 times / hour |

Pumping speed at 500mbar (A) absolute pressure | (m3/h) | 10.1 | 14.0 |

Ultimate vacuum | mbar(A) | 100 | 100 |

Maximum back pressure | mbar(A) | 1300 | 1300 |

Inlet diameter | mm | Φ50 | Φ50 |

Outlet diameter | mm | Φ50 | Φ50 |

Motor model | Y90L-2 |

Applicable voltage/power frequency | V/Hz | Y380V/50Hz | Y440V/60Hz |

Motor power | kW | 2.2 | 2.2 |

speed | rpm | 2840 | 3470 |

Insulation class | F | F |

Protection grade | IP55 | IP55 |

Voltage application range | v | 380/440 | 380/440 |

Applicable ambient temperature | ℃ | +0℃-50℃ | +0℃-50℃ |

Applicable humidity | Class f/95% | Class f/95% |

Working principle of KNCSB series vacuum mixing sewage pump

A certain amount of working liquid is installed in the vacuum sewage mixing pump, and the rotor is eccentric in the pump cavity. The rotor throws the liquid to the outer ring through high-speed rotation, forming a water ring near the shell wall. The water ring acts as a water seal in the pump, forcing the gas to move forward along the shaft in the pump. Because there is more liquid under the pump, the gas is compressed every revolution in the pump, and because the inner diameter of the rotor impeller gradually increases with the flow direction of the fluid, the flow space of the gas in the pump is gradually reduced, and the gas is continuously compressed with the rotation of the rotor, resulting in vacuum. When the sewage collection terminal starts to wash the sewage,the sewage pipeline will suck the sewage into the pipeline by the pressure difference.

The use of vacuum sewage churning pump makes the whole sewage system discharge linearly, without the need for additional auxiliary equipment such as vacuum starting device, flow pipeline and vacuum sealing box, which greatly simplifies the whole system structure, making the whole vacuum sewage system more compact, easy to install, flexible, safe and reliable. What is more important is that the vacuum sewage mixing pump solves the problem of seal leakage.

Structural schematic diagram

with the following benefits:

①Straightforward setup, no need for a vacuum tank, which saves significant space on the ship;

②No formation of foam;

③Efficient vacuum pumping and minimal energy usage;

④Waste can be directly released into any type of sewage processor or collection tank;

⑤Adaptable pipeline installation;

⑥The system is highly dependable.

Operating Environment and Working Conditions

The KYJSB-120 pump is the most commonly used vacuum pump in the KYJSB series of sewage pumps. It is specifically designed for toilets to pump and press waste, including feces, urine, and sewage. This pump is a three-phase flow vacuum churning sewage pump that combines vacuum, churning, and pressure delivery. It is primarily used for transporting various types of sewage in a closed manner, such as in vacuum toilets. It can also be used for transporting general chemical sewage, sludge, and other types of waste.

① The KYJSB vacuum churning sewage pump should be installed in an environment with a temperature range of 0-50°C. If the temperature falls below 0°C, measures should be taken to prevent freezing of the pump.

② Ample space should be provided around the KYJSB vacuum stirring sewage pump to allow for easy daily operation, regular inspection, maintenance, disassembly, and assembly.

③ The KYJSB vacuum agitator blowdown pump should not be left idle. It must have a sufficient liquid level to operate.

④ Whenever possible, neutral water should be used for the vacuum water in the KYJSB vacuum stirring sewage pump. Liquids containing corrosive cleaners or bleach should be minimized.

⑤ The KYJSB vacuum agitation blowdown pump should be regularly inspected and maintained to ensure its proper functioning and longevity.

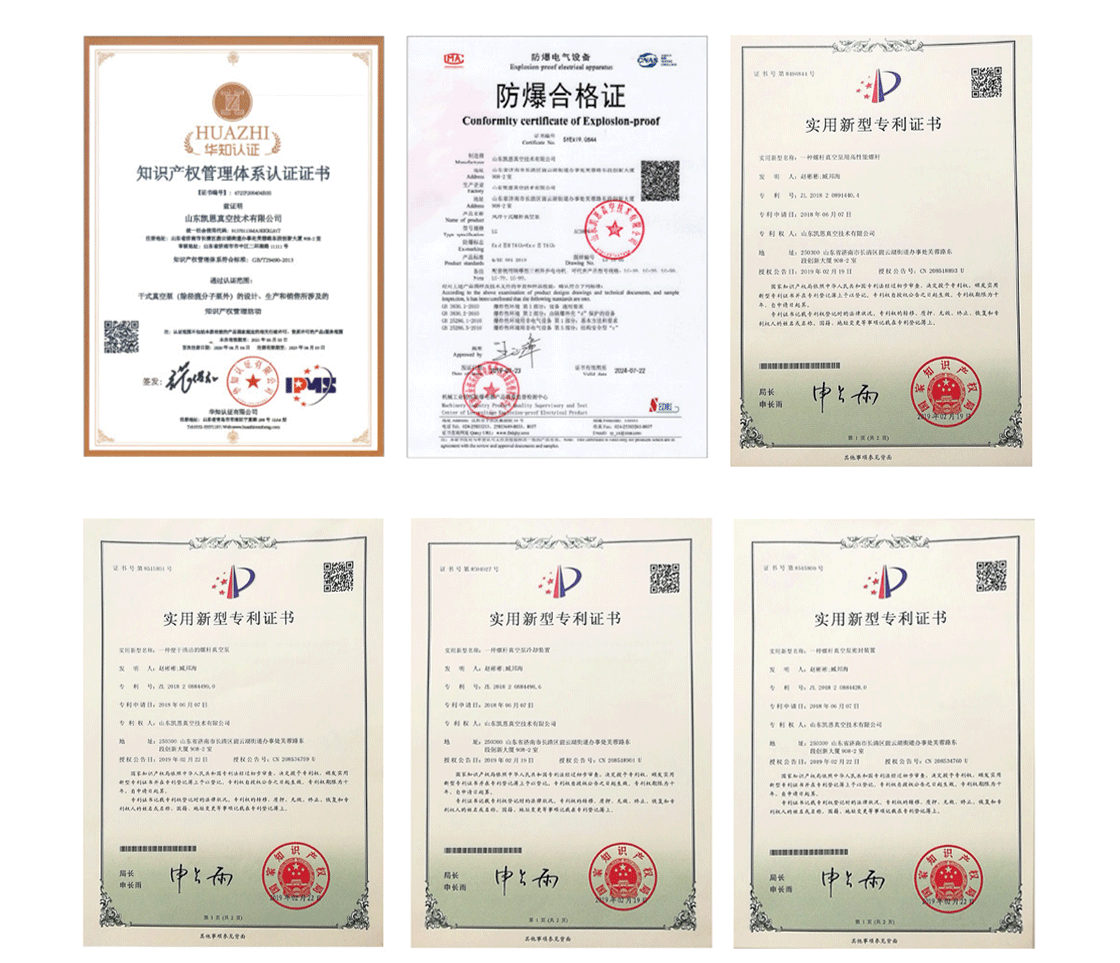

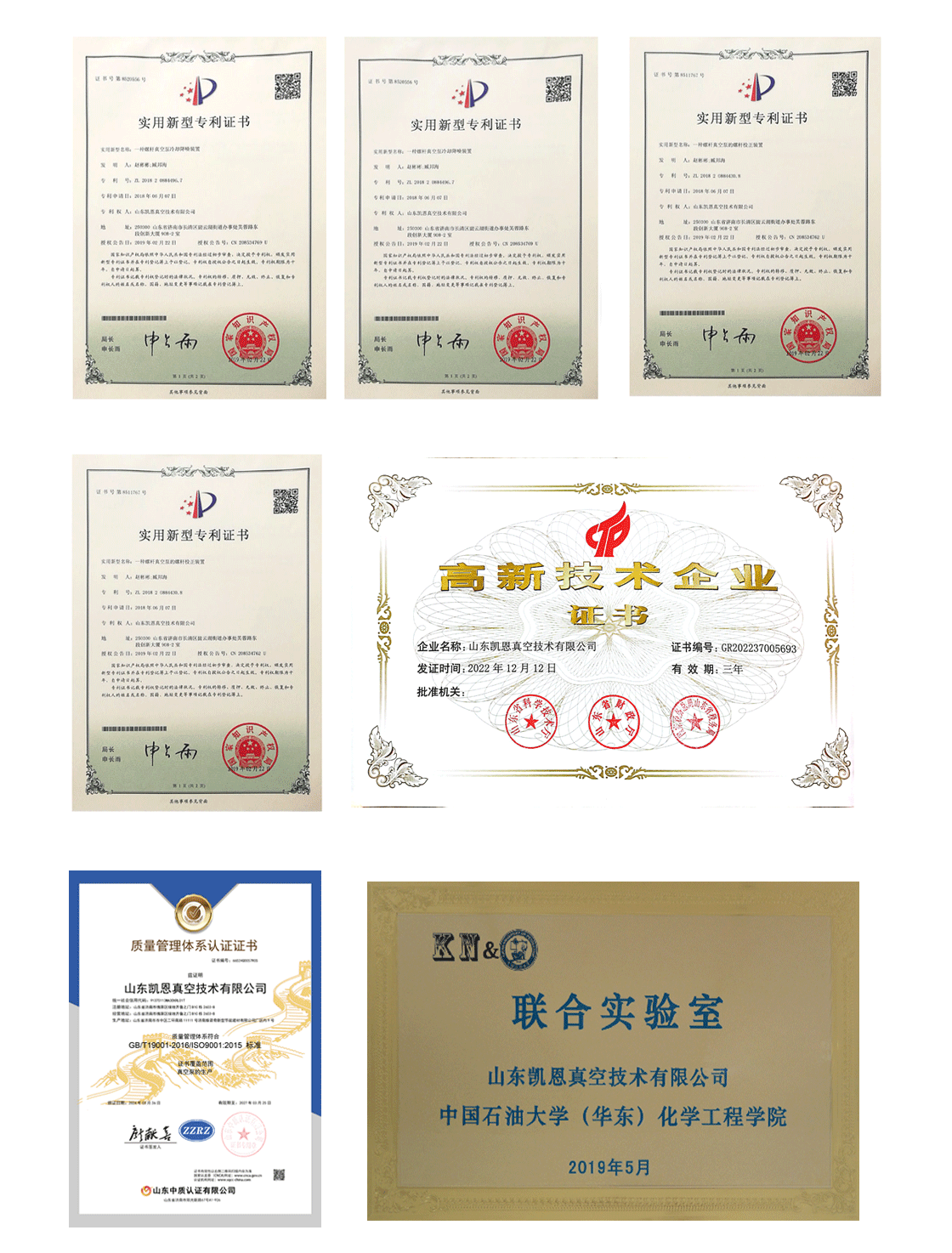

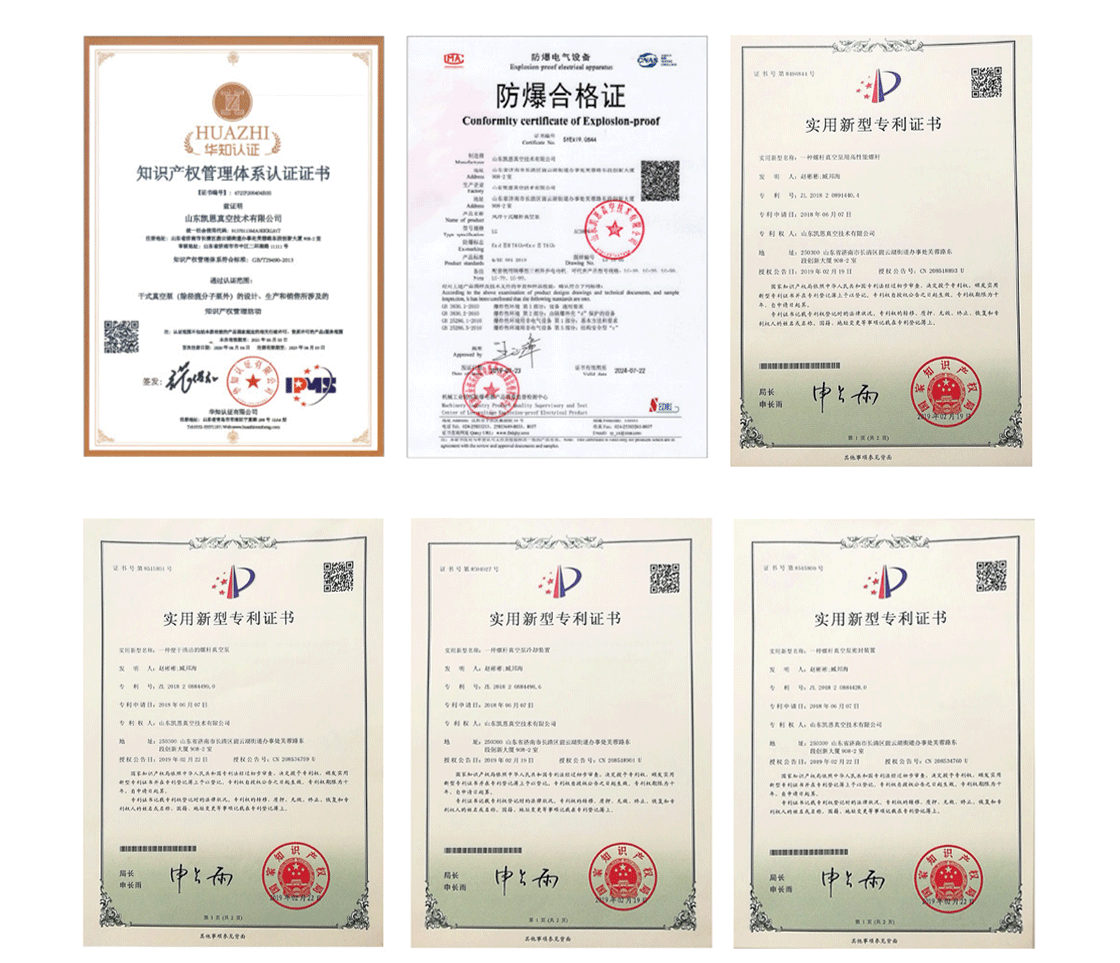

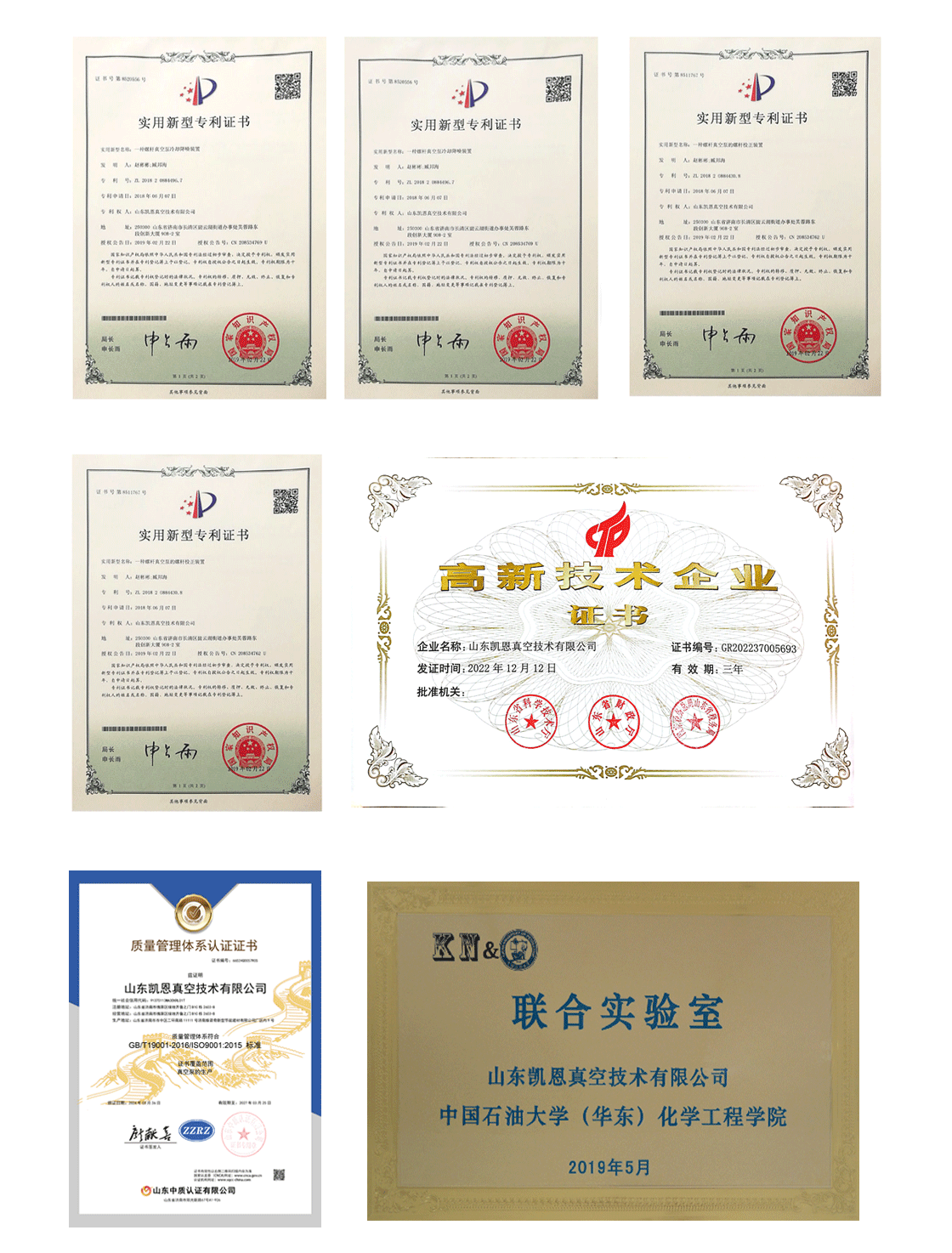

Authoritative certificate

Strong technical strength, excellent equipment, and products strictly managed in accordance with the ISO9001 quality system.