Product Description

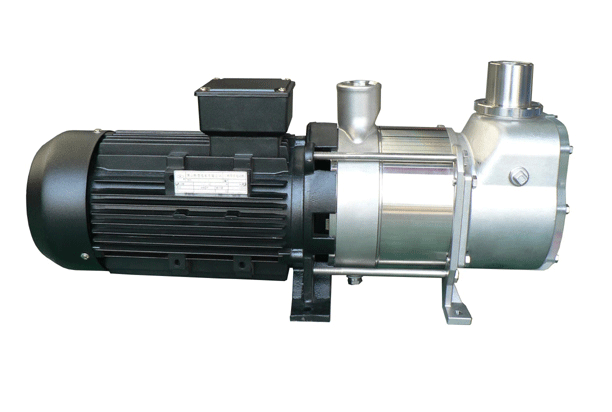

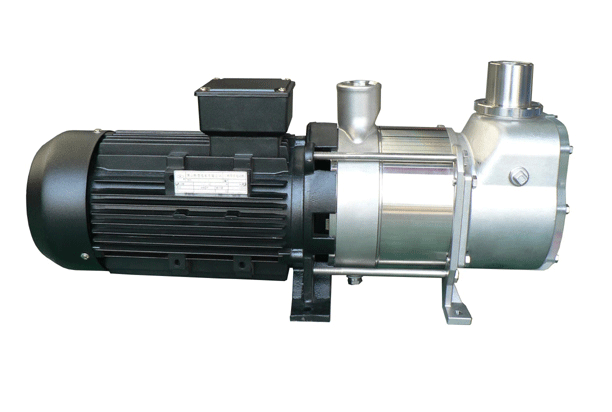

KNCSB series vacuum churning sewage pump is a kind of pump equipment applied to non-gravity sewage discharge of ships. It integrates the functions of vacuum pumping, transportation and churning sewage. It has the characteristics of simple system, low flushing water volume, small sewage collection volume, small pipeline diameter, no inclination requirement, no blockage, flexible installation and layout, strong vertical lifting capacity, low investment and operating costs, and is applicable to modern ships, ships, trains, camping equipment,Pollution discharge from modern buildings, environmentally friendly kitchens, etc.

Features

▲ small size, light weight, quick and flexible installation.

▲ pipeline installation, direct discharge to sewer, sewage treatment plant or collection tank.

▲ multiphase design, the pump can pump and discharge gaseous, liquid and solid combined phases.

▲ low energy consumption.

▲ stainless steel and bronze anti-corrosion materials are used for long service life.

Advantage

① Linear installation, no vacuum tank required, saving a lot of space in the ship;

② No foam;

③ High vacuum pumping efficiency and low energy consumption;

④ The waste can be directly discharged to any specification of sewage processor and sewage collection tank;

⑤ Flexible pipeline installation;

⑥ The system has high reliability.

Working principle

A certain amount of working liquid is installed in the vacuum sewage mixing pump, and the rotor is eccentric in the pump cavity. The rotor throws the liquid to the outer ring through high-speed rotation, forming a water ring near the shell wall. The water ring acts as a water seal in the pump, forcing the gas to move forward along the shaft in the pump. Because there is more liquid under the pump, the gas is compressed every revolution in the pump, and because the inner diameter of the rotor impeller gradually increases with the flow direction of the fluid, the flow space of the gas in the pump is gradually reduced, and the gas is continuously compressed with the rotation of the rotor, resulting in vacuum. When the sewage collection terminal starts to wash the sewage,the sewage pipeline will suck the sewage into the pipeline by the pressure difference.

Performance parameter